We are the fourth generation of Markellos family olive oil producers who keep our family vision of virgin olive oil alive with profound respect for one of nature’s most precious fruit. For years we have successfully supported local producers with great care and deep love for our local tradition.

Our long tradition has taught us that the care taken in each of step of olive oil products not only affects the taste and quality of the olive oil but its cost, yield, and shelf life. Therefore, we greatly focus on providing local producers with reliable and efficient information on every aspect of olive production based on both traditional and modern know-how resources.

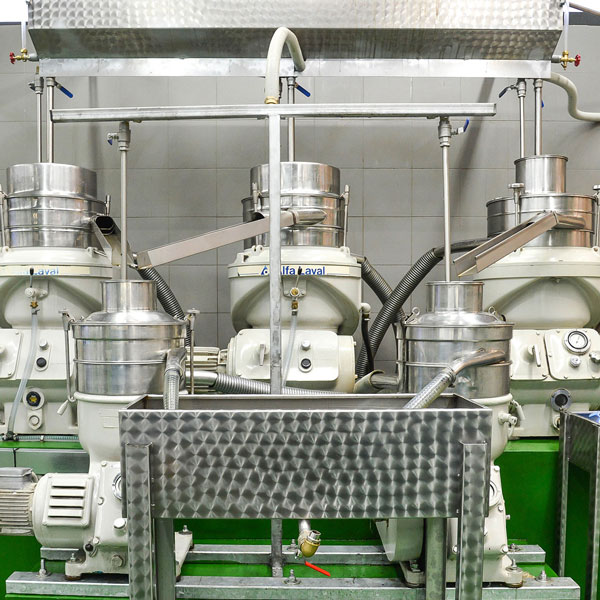

Fully renovated, our olive oil mill boasts all the modern equipment and required certifications (ISO 22000:2005, Compliance to Council Regulation (EC) No 834/2007 on organic production and labelling of organic products) to enable the production of superior quality oil.

After production at our olive oil mill, the extra virgin olive oil is transported to the packaging unit where it is stored in stainless steel tanks (under absolutely controlled conditions) for as long as required.

In addition to tanks and other storage areas, the packaging unit includes two semi-automatic bottling lines (a production line to fill glass bottles and another one for tin canisters).

Olive handling, storage & transportation

The handling and storage of olives in the period between harvesting and milling is critical for oil quality.

The two critical conditions for satisfactory olive handling and storage before milling are:

- Avoid mechanical damage to the olives.

- Control of the time-temperature relationship.

For olive transportation and storage, bins should be used. Strictly avoid putting the olives on the floor or in sacks.

Olive cleaning

Olive cleaning is carried out in two steps. In the first ‘separation’ step, particulate foreign materials are removed by sifting, vibrating screens and air blowing of leaves. In the second ‘washing’ step olives are shaken into a washing basin and finally rinsed with clean water.

The aims of this operation are twofold:

- Removing leaves, as well as pieces of wood, small branches, stones, damaged olives and other particulate material that may have been accidentally collected with the olives.

- Washing dust and soil from the olives.

Olive milling

The aim of milling (by single-grid hammer mill) is to reduce the olives to a homogeneous paste by breaking the pits, skin and pulp cells and the vacuoles containing tiny droplets of oil. The oil flowing freely from the vacuoles can then be separated from the water and the solid constituents. The olive paste is a semiliquid mixture of two different types of solids (rigid pit fragments and soft fleshy parts from the pulp and skin) and two types of immiscible liquids (water and oil).

Olive paste malaxation

Complex physical and biochemical phenomena take place during malaxation with critical effects on the extraction yield as well as on the nutritional and sensory quality of the oil. The aim of malaxation is to make oil separation easier in the subsequent centrifugation steps.

In the malaxing operation, time-temperature conditions should be chosen to maximize the desired and minimize the undesired effects.

Considering the temperature influence on the malaxing operation, it may be observed that

- Coalescence of the oil increases with the increasing in the temperature.

- Diffusion of substances from the aqueous to the oil phase is also accelerated by an increase in temperature.

On the other hand, an excessively high temperature may have detrimental effects on the oil quality due to

- Enzymatic changes involving both lipolytic and oxidative degradation

- Increase in the vapour pressure of the volatile compounds causes some loss of aromas.

Centrifugal separation

Olive paste, derived from the milling and malaxing operations, is the input material for the separation step in the production of extra-virgin olive oil. Olive paste is a heterogeneous mixture of three phases. In order of decreasing density, they are:

- The ‘insoluble solids phase’, consisting of organic semisolid components and the woody fragments from the pit shells. It is 25–30% by weight of the olive paste, with 75% pit fragments and 25% cell wall fragments.

- The ‘aqueous phase’, consisting of water and water-soluble components (salts, simple sugars, simple phenolics and so forth). It is 50–60% of the total paste weight, with 92–95% water and 5–8% soluble solids.

- The ‘oil phase’ consists of 97–99% triglycerides and 1–3% minor components, the latter being a complex mixture of lipophilic, hydrophilic and amphiphilic components with critical roles in sensory and nutritional quality. It is estimated to be 10–23% by weight of the olive paste, depending on cultivar and fruit maturity.

The most important objective of the separation process is to recover as much oil as possible from the olive paste.

The first centrifugation step is carried out with a two-phase decanter in which the oil – the aqueous – and the insoluble solids phases are separated. The insoluble solids and vegetation water are discharged together from the decanter as semi-liquid slurry.

Finishing centrifugation

The oil phase must undergo a second finishing centrifugation for the final removal of water and dispersed solids. Some water is added to improve the centrifuge performance in the oil separation and cleaning. The final product of this centrifugation step is clarified oil, while solid impurities and residual water are discharged as waste.

Extra virgin olive oil & handling

Storage is critical for maintaining the quality of extra-virgin olive oil.

The main risks factors can be listed as follows:

- Temperature abuse.

- Exposure to air (oxygen).

- Exposure to light.

- Presence of water and organic residues in the oil (cloudiness and deposit).

- Lack of hygiene in the oil environment and exposure to contaminated atmosphere.

- Mechanical stress during transfer, pumping, transportation.

+30 2741033328

+30 2741033328